Shop by Category

Permanent Electric Fence Overview

Permanent electric fences utilize an electrified high-tensile wire to contain livestock by training them where the boundaries are. The electric shock given to the livestock does not hurt the animal, but trains them to avoid contact with the fence. Once trained, the electric fence acts as a psychological barrier instead of a physical barrier such as a standard barbwire fence. Less contact with the livestock allows permanent electric fence systems to last longer than barbwire fences with less maintenance. A properly installed and maintained permanent electric fence can last up to 40 years, costs less to install than barbwire fence, and will not injure your livestock.

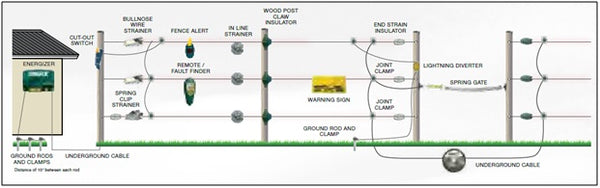

Each electric fence system requires an energizer to electrify the wires. The voltage and power requirements vary by animal type and length of fence. The Southwest Power Fence systems include the proper energizer by application or you can use the energizer selection guide to compare all energizers. Each energizer connects to the hot fence wires, typically through an underground insulated cable, and to the grounding rods. A cut out switch is installed on the main feed to the electric fence to kill the power for maintenance work.

Fence posts are spaced every 20-25 feet to support the electrified wires and an H-brace is required at the end of every straight section of fence. For permanent electric fences wood, steel, or fiberglass fence posts are used. Wood and steel fence posts require an insulator to be installed to attach the wire to the post to prevent grounding the electrified wire. Fiberglass fence posts drilled with mounting holes are naturally non-conductive so an open-eye metal clip can be used instead of a plastic insulator to attach the wire. H-braces are typically built on site from wooden posts or steel pipe filled with concrete. We have provided a design to construct an H-brace. Each Southwest Power Fence system includes the proper combination of fence post, insulator, and mounting hardware or you can compare all fence posts and electric fence insulators.

The electric wire must remain in tension to contain the livestock. Wire strainers are used to keep the fence wire at 225 lbs of tension. We sell several different types of wire strainers and tools that make tensioning the fence wire safe and easy. Each Southwest Power Fence system includes the proper wire strainers required or you can compare all wire strainers.

Fence gates require a break in the electrified fence wire to allow livestock, people, and vehicles through. Joint clamps and underground insulated cables are used to carry the electricity to the other side of the gate where it can be reattached to the fence wires. To prevent livestock from getting through open gates, an electrified spring gate is used to maintain the fence barrier. Spring gate handles make it easy for a person to open the gate and pass through without touching electrified wire or turning off the power to the fence. Each Southwest Power Fence system includes the necessary items to manage gates.

Tools

Operating and maintaining your electric fence requires a few simple tools to make the job much easier. Fault finders, fence alerts, and voltmeters allow you to quickly locate any short in your fence system and check the voltage in the field. Some energizers have remotes that allow the fence power to be turned on and off from anywhere along the fence line for quick maintenance. Lightning diverters prevent damage to your fence by redirecting lightning to ground, and flood gate controllers limit excess energy loss during rising waters during heavy rains near creeks or streams.

Each Southwest Power Fence system includes all of the items required to build a complete electric fence. Please look through our fence systems to find the one that meets your needs.